Background and Mission

ECLIPS Manufacturing is the exciting amalgamation of three companies with a collective experience of over 25 years, delivering over $140m worth of purpose-designed solutions across a myriad of markets including defence, mining, oil and gas, emergency services, infrastructure and the leisure industries.

At ECLIPS Manufacturing, our mission is to design, test, fabricate and deliver logistics systems, rapidly deployable modules, purpose-built structural solutions and leisure products, diligently produced to exceed our customers’ engineering and quality requirements, in order to progressively develop ECLIPS Manufacturing as a globally competitive advanced technology production capability.

Capabilities

We design, fabricate, install, commission and manufacture a wide range of engineered products without the traditional corporate overhead.

Catering to SMEs (the guy next door) through to global industry suppliers. We have catered to manufacturing industries including automotive, defence, mining, marine, leisure, rail, food processing, general manufacturing, commercial, industrial and domestic builders.

Systems Engineering

- Structural Design (Mechanical)

- Process layout and design specific to client’s needs

- CAD Modelling and Analysis

- Verification and Validation Process Analysis and Planning (compliance assurance to key user and legislative requirements)

- Deployable Module Design including advanced security and tempest profiles and electrical, plumbing and renewable energy fit-out design.

| Steel and Aluminium Fabrication |

|

Plastics and Composites |  |

All facets, from concept and prototyping through to production parts (high and low volume).

|

Testing Services

- Industry specific physical testing activities including

- Vibration testing

- Drop test

- Waterproof testing

- Material and Production Verification procedures

- Non Destructive Testing (Liqui Penetrant Testing and Magnetic Particle Testing)

- Destructive Testing – tensile, yield, strength, harness, impact.

Past Performance

- Project and Engineering Services (Systems Engineering)

- Full Design Program/Design Authority: CoA – Project LAND 121 Phase 5B, KJV Gorgon Project – the Container Roll-Out Warehousing System (CROWS™)

- Design, Test and Evaluation Programs: CoA Rapid Prototyping and Development Program – Task 59 Ammunition Carriage

- Original Equipment Manufacturer (OEM) – Logistics Systems

- Australian Defence Force – Joint Modular Intermodal Logistics System (JMILS) – system of systems facilitating factory to firing point logistics

- The Container Roll-Out Warehousing System (CROWS™) – transformational logistics system supporting seamless supplier to work face logistics for complex construction projects

- Steel and Aluminium Fabrication

- Stainless Steel Rooftop Swimming Pool (Richmond, Vic)

- Domestic, commercial, industrial, infrastructure projects

- Marine, mining, aerospace

- Roto-Moulding

- Aquayak Kayaks – 1500/year including six variants

- ADF Stackable Plastic Case (M-CASE) system

- Marine buoy

- Grey water and water tanks

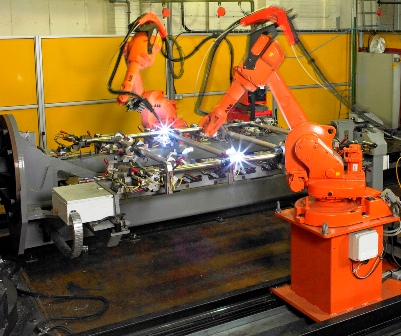

- Robotic Automation and System Control

- Mechanical, Electrical, Hydraulic, Pneumatic Design and Integration

- Concepts through integration or upgrade

- Research & Development

- HMI system design, development, implementation

- Customise Process Plant Design, Fabrication, Installation and Support

- ASKIN Performance Panels – Xflam Paint (VIC).

- Mechanical, Electrical, Hydraulic, Pneumatic Design and Integration

|  |